Capabilities

CNC Machining

Many businesses demand specialized parts to adapt to modern technology and heighten product innovation demands.

Laser Cutting

Laser cutting is a high-precision manufacturing process that uses a concentrated laser beam to cut materials.

Plate Rolling

Plate rolling services are vital in metal fabrication that involves bending and shaping metal plates according to specific specifications and dimensions.

Press Brake

Press brakes are a machine tool utilized in the metalworking industry to bend and shape sheet metal according to specific requirements.

Products

Assemblies

Specifically designed to handle the high pressure, back pressure, maximum flow, and extreme temperatures of your system.

Learn More

Exhaust Systems

Ensure exhaust system integrity with Cenflex custom-designed hard pipe and flexible metal products.

Learn More

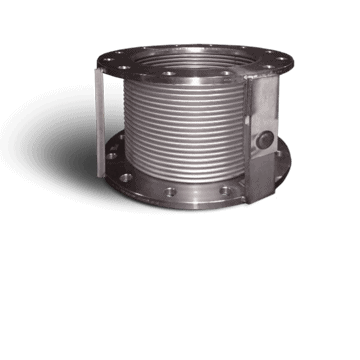

Expansion Joints

Custom-engineered expansion joints help minimize the external stressors that can compromise your system.

Learn More

Flexible Connectors

Flexible connectors bring your system together while minimizing pipe vibration, noise, seismic stresses, and more.

Learn More

Flexible Metal Hoses

Pressure tested to ensure our flexible metal hoses meet or exceed your compatibility and functional requirements.

Learn More

Featured Project

Check out the new information Cenflex just published!

Learn MoreIndustries

Products custom-designed around your application

Services

About Us

In 1992, Scott Sauer founded Cenflex. For almost a decade Cenflex grew and expanded through several locations until finally in 2001 Cenflex constructed its own facility. By 2006, the facility has tripled in size to 40,000 square feet.

Cenflex expanded rapidly after becoming a leader in the supply of flexible metal hose and tube components to the power generation industry. A desire for improvement drove Cenflex to become ISO 9001 certified in 2010 and maintains the certification and drive for constant improvement today.

In 2018 Cenflex expanded by adding a second manufacturing facility. The new facility added an additional 21,685 square feet. The following year, Cenflex went through another big change, second generational ownership and management. With this change came new technology and new services.

Cenflex continues to be an industry leader in flexible metal hose, expansion joints, and fabricator of industrial and commercial exhaust components, but also so much more. After more than 30 years in business Cenflex is truly a one stop shop for all your metal fabrication needs and will continue to grow and invest in new technologies to be a leader in metal fabrications for years to come.