At Cenflex, Inc., we excel at precision manufacturing. Since 1992, we’ve utilized our capabilities in CNC machining, laser cutting, welding, metal finishing, and more to create high-quality products for clients in diverse industries. We strive to be your full-service, one-stop shop for even the most complex metal fabrication projects.

Among our American-made product offerings of hoses, connectors, assemblies, and systems are our well-crafted expansion joints. Read on to learn more about these products, their common applications, and why they’re beneficial in multiple industries.

What Are Expansion Joints?

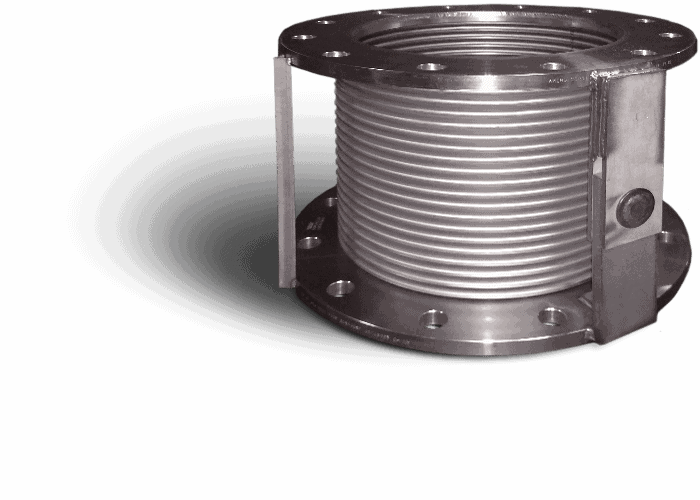

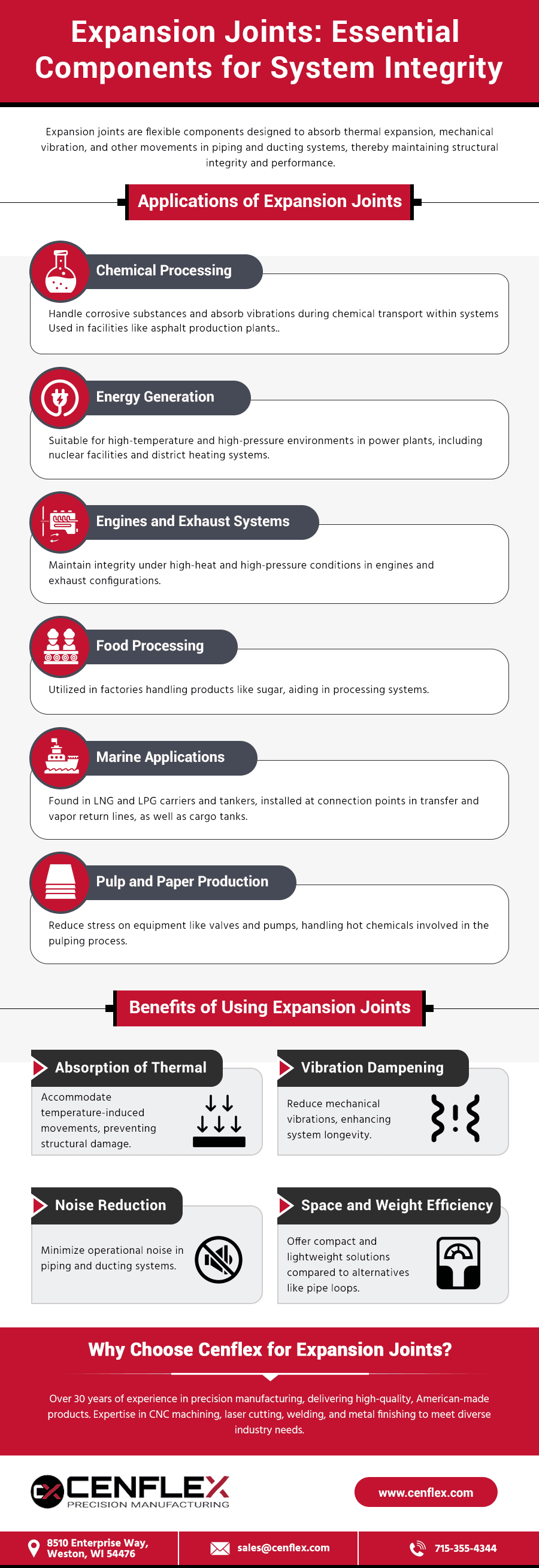

As temperatures in a system or application environment fluctuate, building materials will expand and contract as part of the thermal expansion process. Expansion joints are assemblies that serve to absorb any temperature-based dimensional changes, reliably securing components together for safe operations. These flexible components help prevent the stress within a piping system that would otherwise result in bent or cracked pipes and failed anchors.

Also called movement joints, these assemblies are typically made up of single or multiple metal bellows, with stainless steel being a common material choice. Metals deliver superior strength and can withstand high-heat conditions and corrosive substances. While metal construction offers expansion joints the best versatility, other material options are available, such as plastics like PTFE, rubber, or fabric.

Bellows have a spring-like operation. However, they effectively contain the pressure resulting from the fluid flowing within the joint. This allows flexible expansion joints to react to the connected pipes movements.

Application of Expansion Joints

Diverse industries utilize expansion joints in their applications. You’ll typically find them installed within piping systems and ducts, or close to pumps, turbines, engines, condensers, heat exchangers, and boilers. Common examples include:

- Chemical production and handling. Expansion joints are capable of withstanding corrosive substances and absorbing the vibrations or shocks involved in transporting chemicals within a system. Asphalt production facilities are one example of operations using these joints.

- Energy generation. From district heating systems to nuclear power plants, the energy industry has numerous applications for expansion joints as they can handle high temperatures and pressures.

- Engines and exhaust systems. These joints retain their integrity in the high-heat, high-pressure environments of engine and exhaust systems, as well.

- Food processing. Factories handling products like sugar rely on expansion joints for their processing systems.

- Liquified natural gas/petroleum gas carriers and tankers. In LNG and LPG carriers and tankers, you’ll find expansion joints at connection points in everything from transfer and vapor return lines to cargo tanks.

- Paper and pulp production. Expansion joints are useful for reducing stress on paper mill equipment like valves and pumps, and they can handle the hot chemicals involved in the pulping process.

- Petrochemical processing. Commonly found on oil rigs or in pumping stations and oil refineries, expansion joints won’t degrade when in contact with petrochemical materials.

- Steel manufacturing. Steelmaking is a high-temperature process, and expansion joints successfully handle the resulting thermal expansion in steel plant piping systems, furnaces, and more.

Advantages of Expansion Joints

One primary benefit of using expansion joints is the enhanced lifespan they offer equipment. They improve longevity in piping systems by absorbing the stress at pipes’ load-carrying points and decreasing strain on system pumps. By cutting down on maintenance requirements, expansion joints also benefit an operation by minimizing pipe replacement expenditures.

Expansion joints are advantageous for proper piping alignment as well, and they improve piping system connections. Their performance surpasses that of pipe loops, bends, and other similar options in terms of absorbing significant movement within a piping system. These cost-efficient joints are also ideal for applications with limited space as they’re more compact.

Expansion Joints From Cenflex, Inc.

Cenflex custom-designs and engineers expansion joints specific to a wide variety of industrial applications. Designed around your specific project needs, our expansion joints help minimize the external stressors that can compromise your system — pipe growth and misalignment, engine vibration, pipeline growth, pipe growth without pressure thrust, low and high corrugation, high pressure, extreme temperatures, and seismic disturbances.

Your piping system will only ever be as strong as its weakest joint. Though the many pieces connecting, securing, exhausting, and guiding your system might be small, that doesn’t mean that they’re unimportant. The Cenflex team understands that you don’t have time for subpar products or services. Imperfect machining and welding, imprecise fitting, and production mistakes lead to costly downtime and productivity loss. Cenflex provides customized solutions and is committed to 100% quality flexible metal piping and tubing.

From expansion joints and expansion joint repair to flexible metal hoses and exhaust systems, Cenflex strives to offer high-performance products and comprehensive contract manufacturing services. Contact us to learn more about your expansion joint options, or request a quote today to begin your next project with Cenflex.