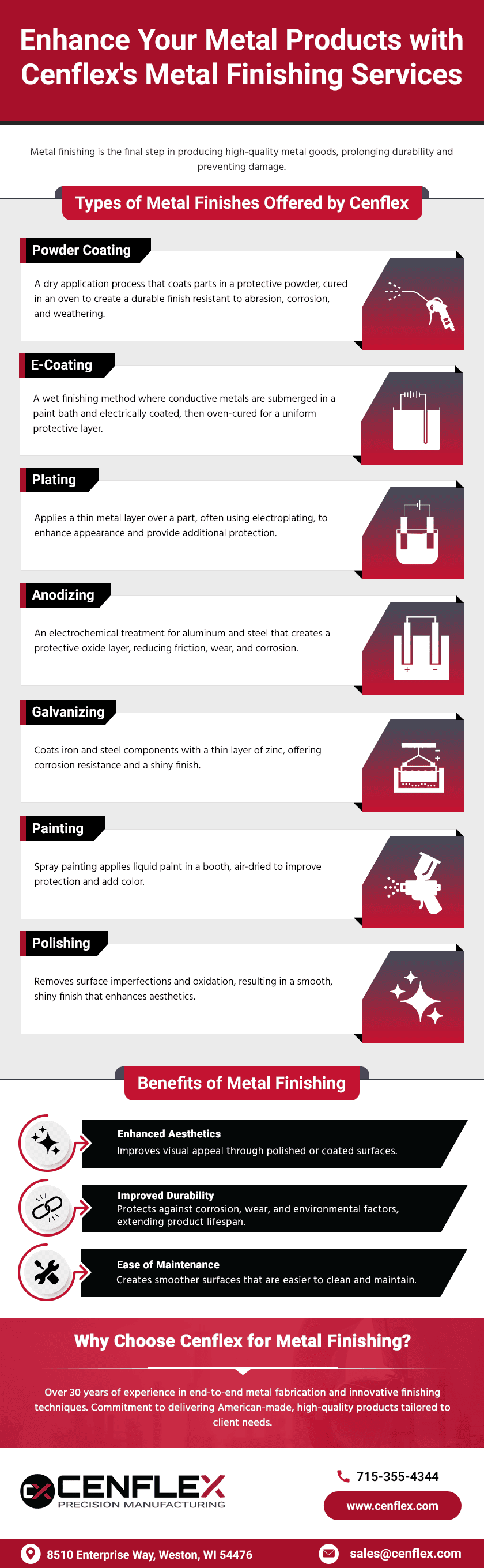

Metal finishing is often the final step in producing high-quality metal goods. Done correctly, these finishing processes will prolong the durability of metallic products and keep them from incurring damage. At Cenflex, Inc., our team specializes in precision manufacturing for custom-engineered components. As part of our turnkey capabilities, we’re experienced in a comprehensive selection of finishing techniques to meet the functional, regulatory, and aesthetic requirements of diverse projects. Read on to learn more about metal finishing, the services we offer, and how they can benefit your products.

What Is Metal Finishing?

Metal finishing is a broad category of techniques responsible for protecting a part surface or enhancing its aesthetics. Coating processes add a protective layer of material on a metal substrate, whereas other finishing methods like polishing and cleaning remove impurities and leave behind smooth, shiny surfaces. We can also combine finishing treatments to increase a component’s resistance capabilities and better prevent damage over time.

Each of the metal finishing services we offer at Cenflex has its own distinct advantages. The ideal process for your project will depend on your component’s material construction, application, and end-use environment.

Types of Metal Finishes

At Cenflex, we offer numerous finishing services to enhance your metal products, including:

- Powder coating. This dry application process coats a part in a protective layer of powder. Placing the part in an oven to cure and harden results in a component with a durable finish that resists abrasion, corrosion, weathering, shifting thermal conditions, and part movement.

- E-coating. The electrical coating process, or e-coating, is a wet finishing method applicable to any conductive metal, such as aluminum, brass, steel, and zinc. This process deposits a coating onto a part electrically as it’s submerged in a paint bath and is then oven-cured.

- Plating. While the terms “plating” and “metal finishing” are sometimes considered interchangeable, this technique applies a thin surface layer of metal overtop a metal part. In electroplating processes, it’s an electric current that deposits metal ions. We’ll commonly utilize additional finishing services like anodizing or painting to enhance abrasion resistance on plated parts.

- Anodizing. Aluminum and steel goods are compatible with the anodizing process, in which we treat part surfaces electrochemically to achieve a protective oxide layer. Anodized parts will experience less friction, wear, and corrosion.

- Galvanizing. Generally for iron and steel components, the galvanization process coats metal parts with a thin layer of zinc to protect them from wear and corrosion while giving the surface a shiny, aesthetically pleasing look.

- Painting. With spray painting, our team will apply a layer of liquid paint across a part’s surface in a paint booth. The coated goods air dry without the help of a curing oven or electrostatic sprayer, ultimately improving part protection and adding color.

- Polishing. The polishing process improves the aesthetics of a metal part, removing imperfections and oxidation from the surface to impart a smooth, shiny finish. This technique also helps protect against degradation.

Benefits of Metal Finishing

Metal finishing processes improve both the form and function of metal goods. For example, painted, coated, or polished products benefit from improved aesthetics for a greater visual appeal. However, finishing treatments are highly practical as well, helping safeguard products against damage. Depending on the type of coating you choose, you can enhance a part’s ability to resist corrosion, water or chemicals, physical wear, temperature changes, and more.

The finished products will also be easier to clean and maintain as the surfaces are smoother, and corrosion-resistant surfaces are typically compatible with water and general-purpose cleaners. Ultimately, investing in metal finishing can enhance longevity and make products better suited to their end-use applications and target market.

Metal Finishing Services From Cenflex, Inc.

Metal finishing processes are an important part of metallic goods fabrication. The Cenflex team provides end-to-end metal fabrication services complemented by innovative finishing techniques to deliver American-made, high-quality products. Over our 30+ years in business, we’ve continually invested in advanced technologies to best serve our clients with optimal, customized solutions now and in the future.

Discover the Cenflex difference today. Contact us to learn more about our fabrication and finishing capabilities, or request a quote to start your order.