Capabilities

Since 1992, Cenflex, Inc. has provided customized solutions to our clients by offering a comprehensive range of metal fabrication services.

From our state-of-the-art, 40,000-square-foot facility, our knowledgeable and experienced team works closely with you to help design, redesign, manufacture, and pressure test everything from metal tubes, pipes, and connectors to full assemblies, exhaust systems, and more.

Whatever your needs, Cenflex is dedicated to providing unparalleled quality and quick turnaround times while keeping you connected with American-made products. Learn more about our full spectrum of service capabilities for fulfilling the requirements of your specific application.

CNC Machining

Computer numerical control (CNC) machining is a collection of subtractive manufacturing processes that utilize pre-programmed software to manipulate cutting equipment like mills, lathes, and grinders. Following the digital instructions, this complex equipment will remove excess material from a workpiece to ultimately create a part or product in the desired shape. CNC machining is beneficial for its precision, repeatability, efficiency, and speed compared to manual manufacturing techniques. Also, this computer-assisted machinery is well-suited to high-volume production, offering scalable solutions and greater cost-efficiency per part.

At Cenflex, our multi-axis CNC machining capabilities enable us to work within your budget to generate per-spec components that adhere to strict quality standards. We proudly partner with businesses in the following industries to deliver CNC machining services:

- Agriculture

- Industrial manufacturing

- Power generation

- Water systems

- Automotive

- Petrochemicals

- Shipbuilding

- Water treatment

- HVAC

Laser Cutting

The word “laser” is an acronym for “light amplification by stimulated emission of radiation.” In laser cutting, the manufacturing process uses a concentrated beam of high-energy light to cut through materials in sheet or plate format with precision. The technique efficiently generates two-dimensional components for diverse applications using localized heating, melting, or vaporization.

The Cenflex team has the expertise and the resources to meet the laser cutting demands of myriad industries. Our equipment and capabilities related to this process include:

- CO2 and fiber laser options, including 4.4 KW CO2 and 9K Fiber

- State-of-the-art cutting tables sized at 120”x60”

- Creating clean cuts in material thicknesses up to 1”

- Material choices of steel, carbon steel, stainless steel, aluminum, brass, and copper

Welding

This fabrication method effectively fuses two or more parts together to generate a permanent bond between them. Depending on the welding technique, the process will make use of pressure, high heat, or both to create a strong welded joint. Our experienced welding team works with a variety of metal material options, such as carbon steel, stainless steel, and specialty alloys. To fabricate beams, tubes, channels, angles, or other high-quality structural shapes in multiple sizes, we offer the following welding services:

- Metal inert gas (MIG) welding

- Tungsten inert gas (TIG) welding

Plate Rolling

Generating curved components in conical, cylindrical, and elliptical configurations, among others, this fabrication technique shapes plates of various metals according to your desired dimensions and specifications. It creates the necessary curvature in a material by applying bending force, resulting in strong, consistent, and seamless parts of various sizes and shapes that require little welding. The plate rolling process can accommodate the following types of materials in creating these tight-tolerance parts:

- Alloys

- Aluminum

- Carbon steel

- Stainless steel

- Heat-resistant metals

- Wear-resistant plates

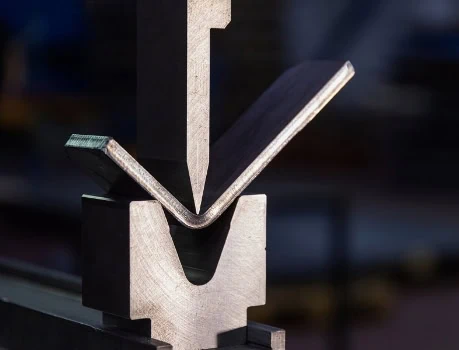

Press Braking

The metalworking sector relies on the press braking process to bend metal sheet until it acquires the preferred profile based on your project’s needs. Press braking combines a mechanical or hydraulic press, an upper and lower die, and compression force to produce the necessary angle or shape. From fabricating standard metal components to producing precision-engineered parts, this equipment is compatible with many different applications.

Our press braking services allow us to assist clients in markets like construction, automotive, and aerospace. To best meet the requirements of these diverse projects, Cenflex is experienced in the following processes using our advanced press brake technology:

- Precision bending

- Sheet metal forming

- Custom metal fabrication

Metal Finishing

Metal finishing services encompass all of the methods necessary for preparing a metal component and applying a surface coating to improve or better protect the part. Finishing typically begins with cleaning and polishing operations to smooth a substrate and make it receptive to receiving the coating. Then, through techniques ranging from electroless and electroplating to painting, you can improve upon a part’s strength as well as its resistance to rust and corrosion.

To achieve the highest standards of excellence and quality in our finishing services, Cenflex recently invested in a Cardinal shot blast machine and finished upgrading our paint system. Our two Global Finishing Solutions (GFS) industrial paint booths enhance our wet paint capabilities.

Custom-Engineered Capabilities From Cenflex, Inc.

Cenflex has delivered turnkey metal fabrication services to a diverse client base for more than three decades. As part of our commitment to quality and continual improvement, our ISO 9001:2015-certified company continues to expand our offerings and invest in cutting-edge technologies. This allows us to live up to our reputation as an industry-leading one-stop shop for unsurpassed metal fabrication services and custom-engineered solutions.

Contact us to learn more about our capabilities and how Cenflex can support your business, or request a quote today to discuss the specific needs of your next project.