Many businesses demand specialized parts to adapt to modern technology and heighten product innovation demands. Thus, they look to computer numerical control (CNC) machining to execute precise plans and produce accurate items using computer software.

The development of computers and machines has made it possible for the CNC machining process to produce more complicated custom designs than traditional production techniques. These machined parts are used in various industries, including the medical sector, construction, manufacturing, aerospace, and transportation.

What Is CNC Machining?

In CNC machining, the production equipment is operated by pre-programmed software and code. The use of complicated machinery — such as grinders, lathes, and turning mills — to cut, shape, and produce various components and prototypes is also controlled by CNC machining.

CNC machinery operators combine mathematical ideas, technical drawings, mechanical design, and computer programming to make metal and plastic parts, such as manufacturing crucial vehicle or airplane components out of sheet metal.

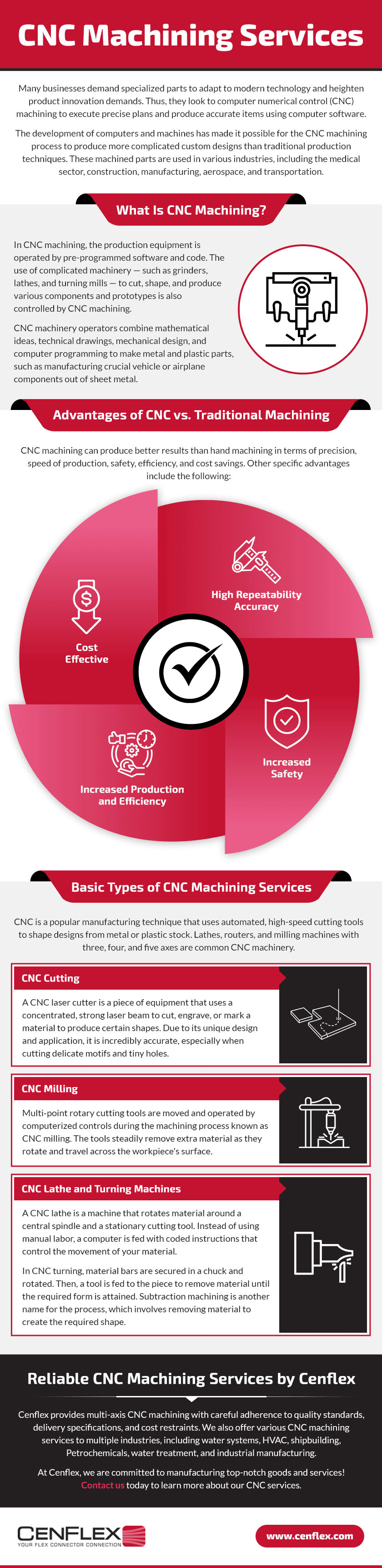

Advantages of CNC vs. Traditional Machining

CNC machining can produce better results than hand machining in terms of precision, speed of production, safety, efficiency, and cost savings. Other specific advantages include the following:

High Repeatability Accuracy

Compared to manual machining, CNC processes are more precise and may be repeatedly performed without significant quality and specification variations, ensuring uniform components.

Increased Production and Efficiency

Since CNC machining is automated, the parts maintain a higher quality while reducing turnaround times. In addition, it is more effective than manual machining because machines do not require significant break times.

Increased Safety

CNC machines run behind a guard or a closed, transparent safety door, making them far safer than manually operated machines.

Cost Effective

Most equipment in traditional machining processes require one operator each. Since an experienced operator may operate multiple CNC machines simultaneously, this method requires less staffing. In addition, CNC decreases production process errors and eliminates extra waste.

Basic Types of CNC Machining Services

CNC is a popular manufacturing technique that uses automated, high-speed cutting tools to shape designs from metal or plastic stock. Lathes, routers, and milling machines with three, four, and five axes are common CNC machinery.

CNC Cutting

A CNC laser cutter is a piece of equipment that uses a concentrated, strong laser beam to cut, engrave, or mark a material to produce certain shapes. Due to its unique design and application, it is incredibly accurate, especially when cutting delicate motifs and tiny holes.

CNC Milling

Multi-point rotary cutting tools are moved and operated by computerized controls during the machining process known as CNC milling. The tools steadily remove extra material as they rotate and travel across the workpiece’s surface.

CNC Lathe and Turning Machines

A CNC lathe is a machine that rotates material around a central spindle and a stationary cutting tool. Instead of using manual labor, a computer is fed with coded instructions that control the movement of your material.

In CNC turning, material bars are secured in a chuck and rotated. Then, a tool is fed to the piece to remove material until the required form is attained. Subtraction machining is another name for the process, which involves removing material to create the required shape.

Reliable CNC Machining Services by Cenflex

Cenflex provides multi-axis CNC machining with careful adherence to quality standards, delivery specifications, and cost restraints. We also offer various CNC machining services to multiple industries, including water systems, HVAC, shipbuilding, Petrochemicals, water treatment, and industrial manufacturing.

At Cenflex, we are committed to manufacturing top-notch goods and services! Contact Us today to learn more about our CNC services.