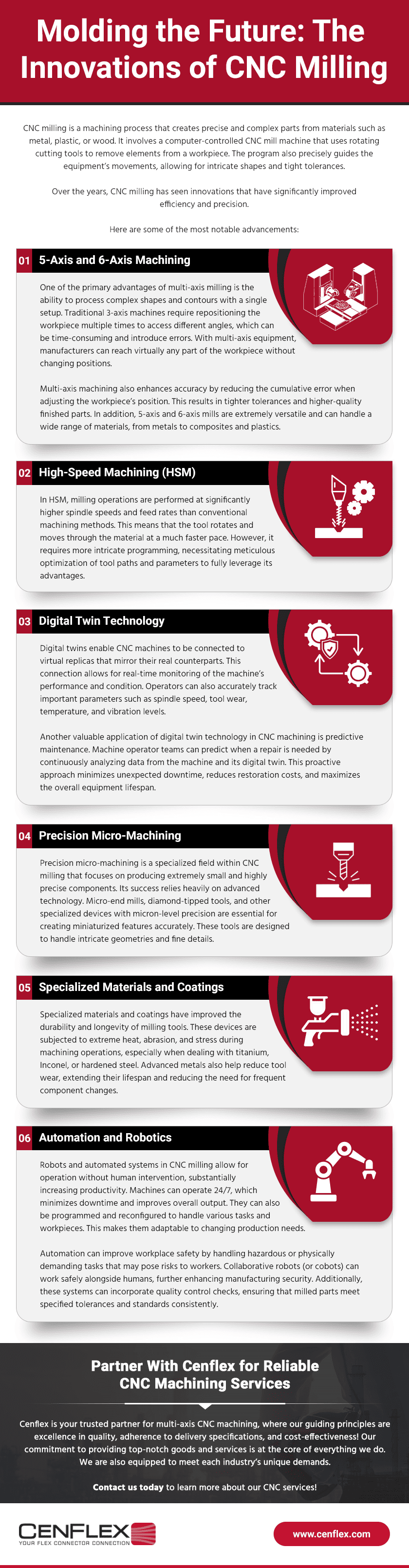

CNC milling is a machining process that creates precise and complex parts from materials such as metal, plastic, or wood. It involves a computer-controlled CNC mill machine that uses rotating cutting tools to remove elements from a workpiece. The program also precisely guides the equipment’s movements, allowing for intricate shapes and tight tolerances.

Over the years, CNC milling has seen innovations that have significantly improved efficiency and precision. Here are some of the most notable advancements:

1. 5-Axis and 6-Axis Machining

One of the primary advantages of multi-axis milling is the ability to process complex shapes and contours with a single setup. Traditional 3-axis machines require repositioning the workpiece multiple times to access different angles, which can be time-consuming and introduce errors. With multi-axis equipment, manufacturers can reach virtually any part of the workpiece without changing positions.

Multi-axis machining also enhances accuracy by reducing the cumulative error when adjusting the workpiece’s position. This results in tighter tolerances and higher-quality finished parts. In addition, 5-axis and 6-axis mills are extremely versatile and can handle a wide range of materials, from metals to composites and plastics.

2. High-Speed Machining (HSM)

In HSM, milling operations are performed at significantly higher spindle speeds and feed rates than conventional machining methods. This means that the tool rotates and moves through the material at a much faster pace. However, it requires more intricate programming, necessitating meticulous optimization of tool paths and parameters to fully leverage its advantages.

3. Digital Twin Technology

Digital twins enable CNC machines to be connected to virtual replicas that mirror their real counterparts. This connection allows for real-time monitoring of the machine’s performance and condition. Operators can also accurately track important parameters such as spindle speed, tool wear, temperature, and vibration levels.

Another valuable application of digital twin technology in CNC machining is predictive maintenance. Machine operator teams can predict when a repair is needed by continuously analyzing data from the machine and its digital twin. This proactive approach minimizes unexpected downtime, reduces restoration costs, and maximizes the overall equipment lifespan.

4. Precision Micro-Machining

Precision micro-machining is a specialized field within CNC milling that focuses on producing extremely small and highly precise components. Its success relies heavily on advanced technology. Micro-end mills, diamond-tipped tools, and other specialized devices with micron-level precision are essential for creating miniaturized features accurately. These tools are designed to handle intricate geometries and fine details.

5. Specialized Materials and Coatings

Specialized materials and coatings have improved the durability and longevity of milling tools. These devices are subjected to extreme heat, abrasion, and stress during machining operations, especially when dealing with titanium, Inconel, or hardened steel. Advanced metals also help reduce tool wear, extending their lifespan and reducing the need for frequent component changes.

6. Automation and Robotics

Robots and automated systems in CNC milling allow for operation without human intervention, substantially increasing productivity. Machines can operate 24/7, which minimizes downtime and improves overall output. They can also be programmed and reconfigured to handle various tasks and workpieces. This makes them adaptable to changing production needs.

Automation can improve workplace safety by handling hazardous or physically demanding tasks that may pose risks to workers. Collaborative robots (or cobots) can work safely alongside humans, further enhancing manufacturing security. Additionally, these systems can incorporate quality control checks, ensuring that milled parts meet specified tolerances and standards consistently.

Partner With Cenflex for Reliable CNC Machining Services

Cenflex is your trusted partner for multi-axis CNC machining, where our guiding principles are excellence in quality, adherence to delivery specifications, and cost-effectiveness! Our commitment to providing top-notch goods and services is at the core of everything we do. We are also equipped to meet each industry’s unique demands.

Contact us today to learn more about our CNC services!