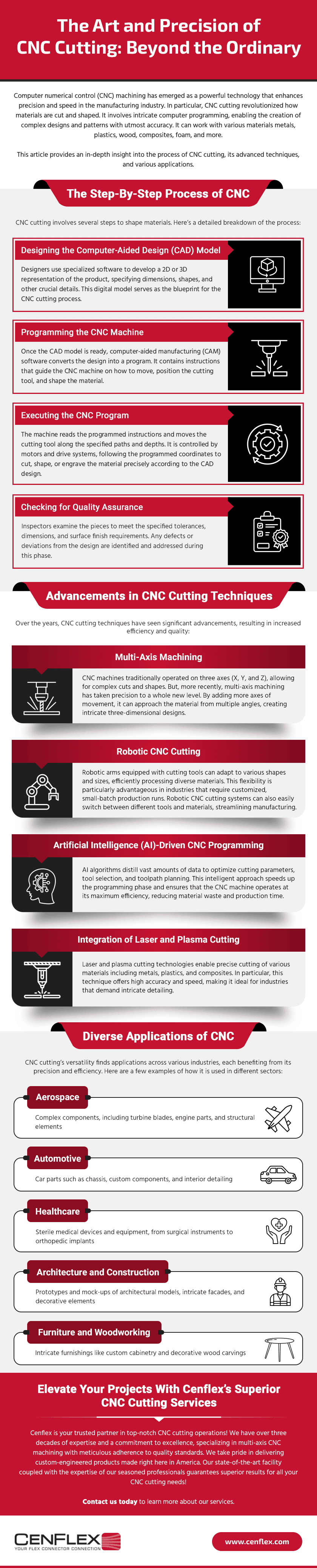

Computer numerical control (CNC) machining has emerged as a powerful technology that enhances precision and speed in the manufacturing industry. In particular, CNC cutting revolutionized how materials are cut and shaped. It involves intricate computer programming, enabling the creation of complex designs and patterns with utmost accuracy. It can work with various materials metals, plastics, wood, composites, foam, and more.

This article provides an in-depth insight into the process of CNC cutting, its advanced techniques, and various applications.

The Step-By-Step Process of CNC Cutting

CNC cutting involves several steps to shape materials. Here’s a detailed breakdown of the process:

1. Designing the Computer-Aided Design (CAD) Model

Designers use specialized software to develop a 2D or 3D representation of the product, specifying dimensions, shapes, and other crucial details. This digital model serves as the blueprint for the CNC cutting process.

2. Programming the CNC Machine

Once the CAD model is ready, computer-aided manufacturing (CAM) software converts the design into a program. It contains instructions that guide the CNC machine on how to move, position the cutting tool, and shape the material.

3. Executing the CNC Program

The machine reads the programmed instructions and moves the cutting tool along the specified paths and depths. It is controlled by motors and drive systems, following the programmed coordinates to cut, shape, or engrave the material precisely according to the CAD design.

4. Checking for Quality Assurance

Inspectors examine the pieces to meet the specified tolerances, dimensions, and surface finish requirements. Any defects or deviations from the design are identified and addressed during this phase.

Advancements in CNC Cutting Techniques

Over the years, CNC cutting techniques have seen significant advancements, resulting in increased efficiency and quality:

Multi-Axis Machining

CNC machines traditionally operated on three axes (X, Y, and Z), allowing for complex cuts and shapes. But, more recently, multi-axis machining has taken precision to a whole new level. By adding more axes of movement, it can approach the material from multiple angles, creating intricate three-dimensional designs.

Robotic CNC Cutting

Robotic arms equipped with cutting tools can adapt to various shapes and sizes, efficiently processing diverse materials. This flexibility is particularly advantageous in industries that require customized, small-batch production runs. Robotic CNC cutting systems can also easily switch between different tools and materials, streamlining manufacturing.

Artificial Intelligence (AI)-Driven CNC Programming

AI algorithms distill vast amounts of data to optimize cutting parameters, tool selection, and toolpath planning. This intelligent approach speeds up the programming phase and ensures that the CNC machine operates at its maximum efficiency, reducing material waste and production time.

Integration of Laser and Plasma Cutting

Laser and plasma cutting technologies enable precise cutting of various materials including metals, plastics, and composites. In particular, this technique offers high accuracy and speed, making it ideal for industries that demand intricate detailing.

Diverse Applications of CNC Cutting

CNC cutting’s versatility finds applications across various industries, each benefiting from its precision and efficiency. Here are a few examples of how it is used in different sectors:

- Aerospace: complex components, including turbine blades, engine parts, and structural elements

- Automotive: car parts such as chassis, custom components, and interior detailing

- Healthcare: sterile medical devices and equipment, from surgical instruments to orthopedic implants

- Architecture and construction: prototypes and mock-ups of architectural models, intricate facades, and decorative elements

- Furniture and woodworking: intricate furnishings like custom cabinetry and decorative wood carvings

Elevate Your Projects With Cenflexs Superior CNC Cutting Services

Cenflex is your trusted partner in top-notch CNC cutting operations! We have over three decades of expertise and a commitment to excellence, specializing in multi-axis CNC machining with meticulous adherence to quality standards. We take pride in delivering custom-engineered products made right here in America. Our state-of-the-art facility coupled with the expertise of our seasoned professionals guarantees superior results for all your CNC cutting needs!

Contact us today to learn more about our services.